Evolving Everyday

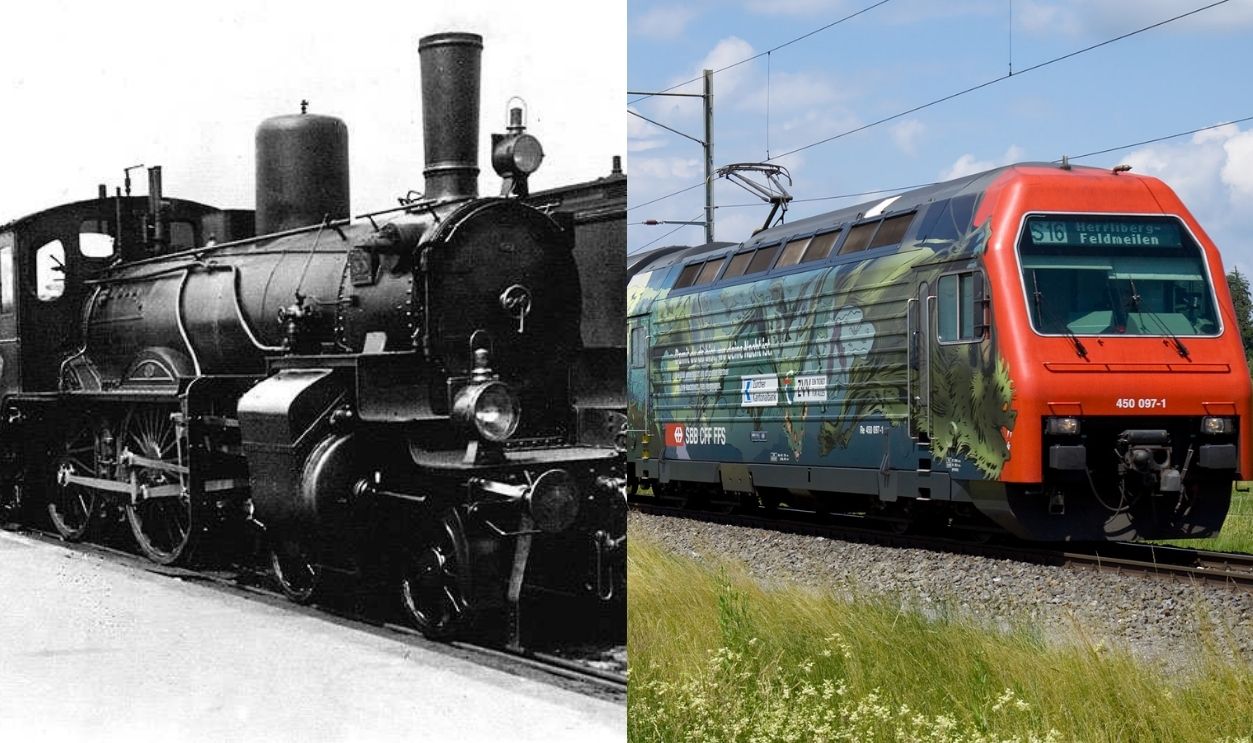

We are currently at a point where hydrogen could be used to run America’s railways. How on earth did we go from steam engines to hydrotech? Read on.

The Ultimate American Rail Trip From Steam To Diesel To Electric

Centuries back, a train voyage took days. Today, depending on the model, it could take you minutes. So, let’s tackle all the locomotive feats over the years that made this happen.

What’s The Difference: A Locomotive And A Train?

A locomotive is the engine that pulls or pushes the train along the tracks, and it is powered by diesel, electricity, or steam. It can be on the back, center, or front. A train is a connection of rail cars with one or more locomotives linked to cargo and passenger cars.

Are All Cars On A Train Locomotives?

No. Only the ones that provide motive power to push or pull the train. All the rest are called rolling stock, and they can carry people, cargo, and animals. They can also be cabooses—final cars (mainly in older train models) where the crew could monitor trains or use as accommodation.

Marcus Wong Wongm, CC BY-SA 4.0, Wikimedia Commons

Marcus Wong Wongm, CC BY-SA 4.0, Wikimedia Commons

Locomotive Terminology 101

Road numbers are locomotive or rolling stock number identifiers. A model refers to a specific design or type like the EMD F7 or GE Dash 9—each has its own specs. Railroads are companies that own or operate trains or tracks like Union Pacific (owns) or Nashville & Eastern Railroad (operates). Let’s get started on the locomotives.

ShajiA at Malayalam Wikipedia, Wikimedia Commons

ShajiA at Malayalam Wikipedia, Wikimedia Commons

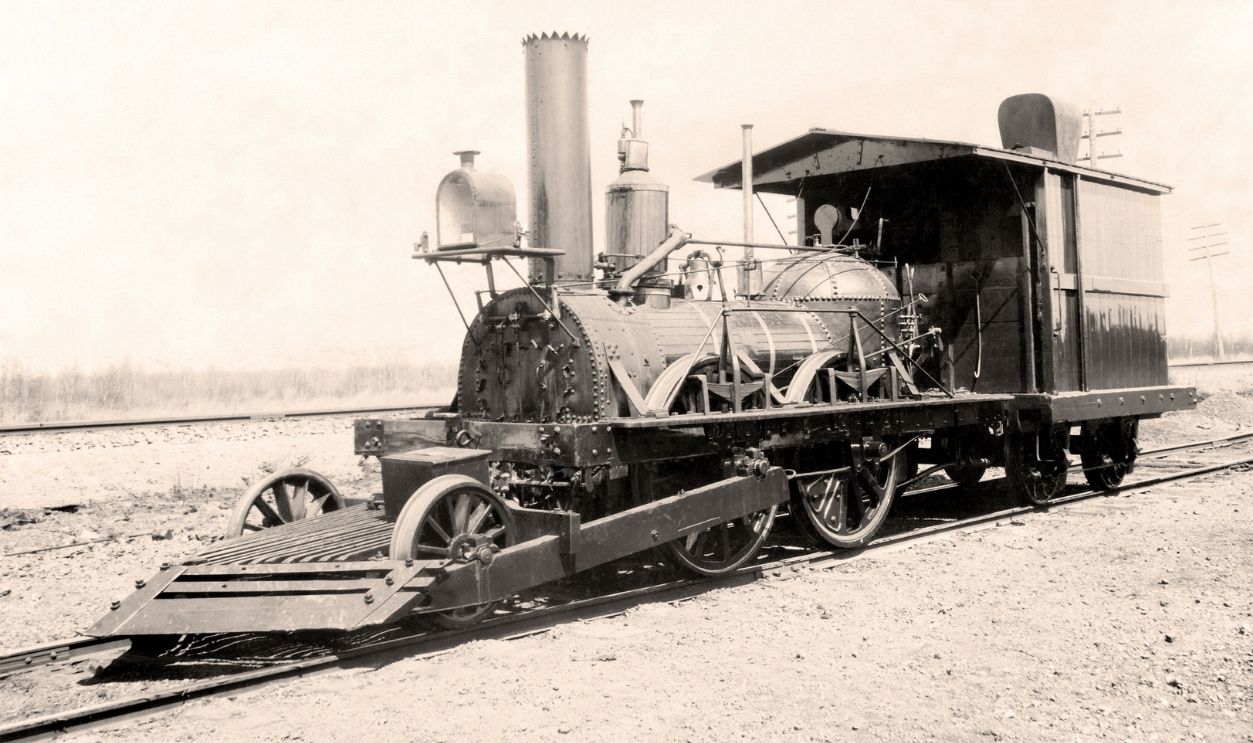

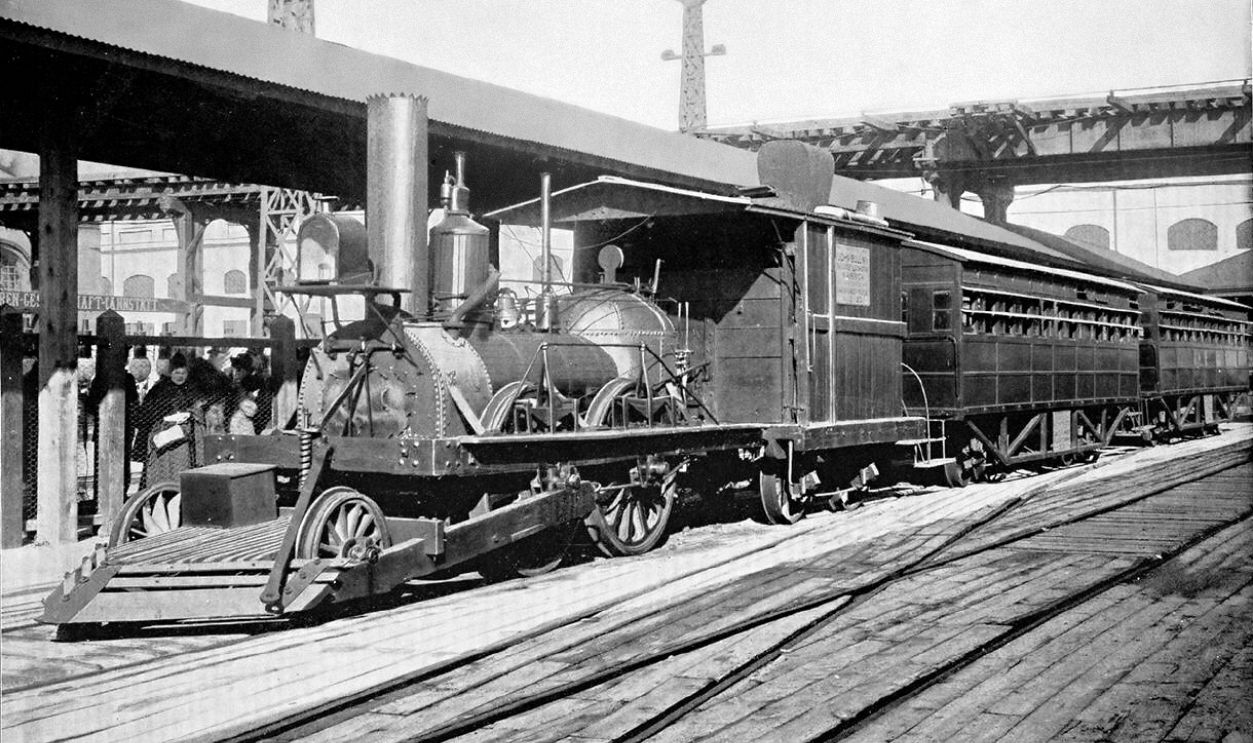

John Bull (1831)

John Bull was a Robert Stephenson and Company 1831 creation, and it was a steam locomotive built in Newcastle, England. It got to America thanks to the Camden and Amboy Railroad who purchased it and brought it to New Jersey. The name was inspired by the fictional English gentleman.

Unknown Author, Wikimedia Commons

Unknown Author, Wikimedia Commons

Lots Of Modifications Ensued

This steam engine was originally built as a 0-4-0 (later modified to 2-4-0). In simple terms, it was built with no guiding wheels, four driving wheels, and no trailing wheels. Later, it was modified to have two leading wheels, four driving wheels, and no back wheels.

Unknown Author, Wikimedia Commons

Unknown Author, Wikimedia Commons

First And Last Journey

Its first run was on September 15, 1831 by the Smithsonian Institution. After 1866, Camden and Amboy Railroad stored it. The Pennsylvania Railroad later refurbished and operated it for public displays, including the Centennial Exposition in 1876 and the National Railway Appliance Exhibition in 1883.

Toby from Everywhere, USA, CC BY-SA 2.0, Wikimedia Commons

Toby from Everywhere, USA, CC BY-SA 2.0, Wikimedia Commons

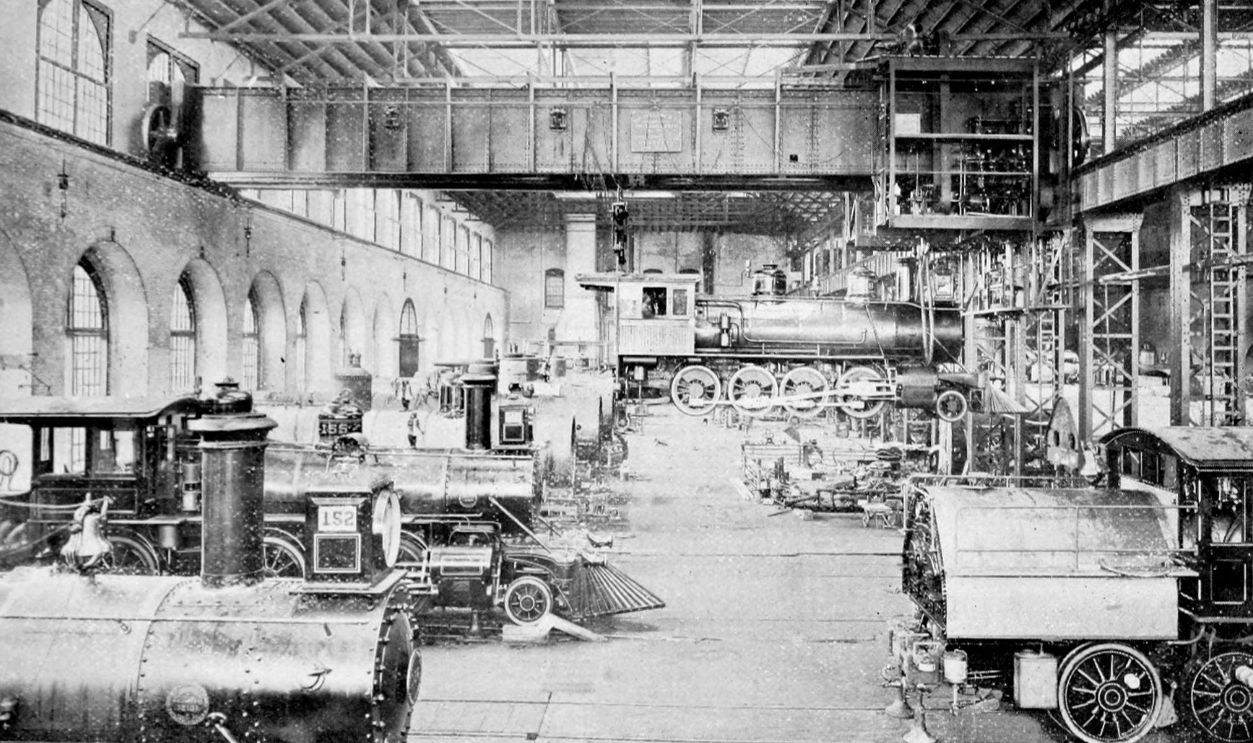

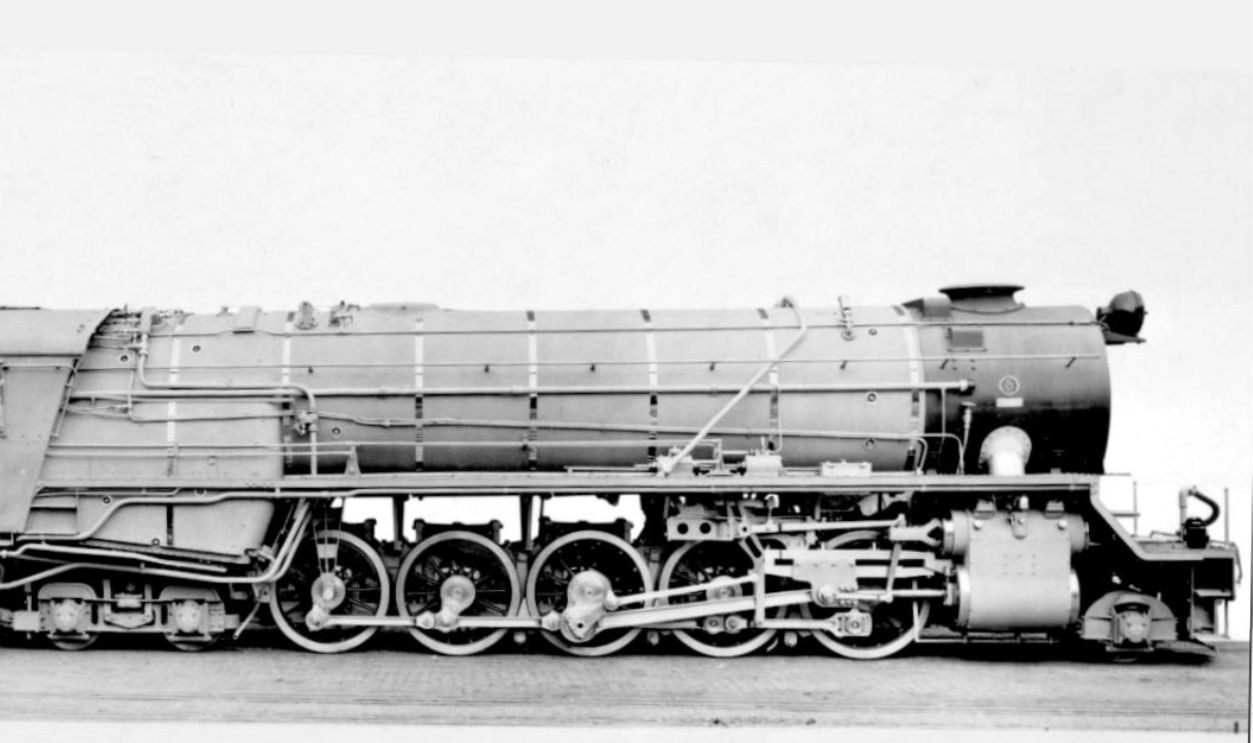

Baldwin Locomotive Works Mallet Locomotives (Early 1900s)

A few years down the line, the Baldwin Locomotive Works Mallet Locomotives became another set of steam locomotives to operate on American soil. Anatole Mallet, a Swiss engineer, ensured the engine was larger and more powerful than the John Bull. Each had two pairs of cylinders—simply put, two engines on one frame.

Horace L.Arnold, Wikimedia Commons

Horace L.Arnold, Wikimedia Commons

Built For Steep Terrains

The double engine offers the locomotives greater horsepower and traction such that now, they could move through tight spaces and take on steep terrains. Their wheel alignment was 2-6-6-2; two leading wheels, six driving wheels, six more driving wheels, and two trailing wheels. There were other Mallet Locomotives with different configurations.

Harold Bartle Phelps Sr., Wikimedia Commons

Harold Bartle Phelps Sr., Wikimedia Commons

Reasons For Its Downfall

Due to the added terrain advantages, these versions were popular in mountainous locations. They remained in service until the late 1950s, and the Norfolk & Western Railway was among the last to use them. The decline started because of the Great Depression and the rise of diesel locomotives.

Baldwinlocomotiveworks - R.A. Sallinen III, CC BY-SA 3.0, Wikimedia Commons

Baldwinlocomotiveworks - R.A. Sallinen III, CC BY-SA 3.0, Wikimedia Commons

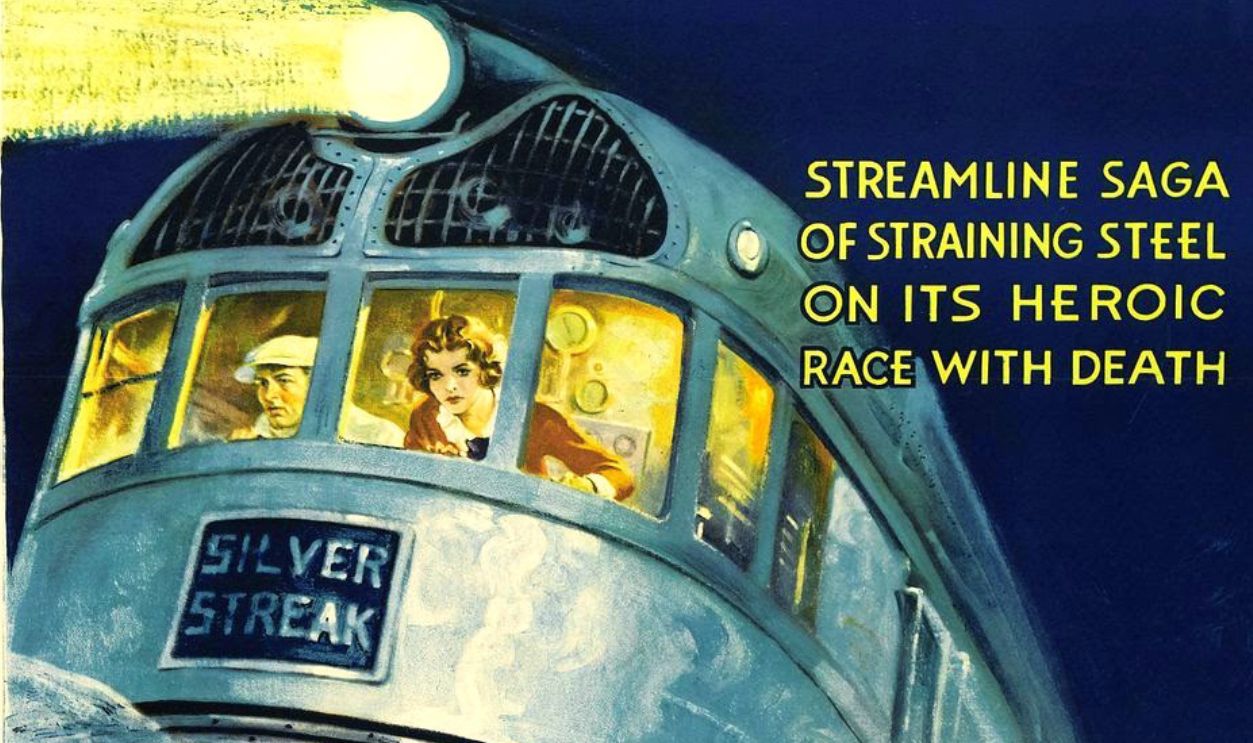

Burlington Zephyr (1934)

This locomotive model marked its position on this list with multiple firsts. It was the first American diesel-electric powered passenger train. It was also the pioneering revenue service locomotive—the first of its kind for making money. Another first? It hit a record speed on a non-stop trip from Denver to Chicago. Speed? Time?

Roger Wollstadt from Sarasota, Florida, CC BY-SA 2.0, Wikimedia Commons

Roger Wollstadt from Sarasota, Florida, CC BY-SA 2.0, Wikimedia Commons

It Inspired Art

At one point, Burlington moved at a speed of 112.5 mph (181 km/h), reaching Chicago in just 13 hours and 5 minutes. Ever heard of the movie The Silver Streak? This was the inspiration for that 1934 film. It even made this locomotive acquire the nickname “The Silver Streak.”

Copyright RKO, Wikimedia Commons

Copyright RKO, Wikimedia Commons

The Name Change

While we are still on names, the Burlington Zephyr had a name change. After the Great Depression, the passenger rail business took a major hit, but this locomotive was more like a comeback. So, it became Pioneer Zephyr, and Burlington expanded its operations, which came to an end in 1960.

Slambo, CC BY-SA 4.0, Wikimedia Commons

Slambo, CC BY-SA 4.0, Wikimedia Commons

Union Pacific Big Boy (1941–1944)

There were 25 American Locomotive Company (ALCO) Big Boy locomotives on the 4-8-8-4 wheel arrangement built and their job was to haul cargo over the hilly Wasatch Range. This was between Ogden, Utah, and Green River, Wyoming. Later, they were reassigned to other routes.

The Origin Of Its Name

If you’re wondering where the name came from, here it is. Allegedly, when a worker from ALCO first laid their eyes on the machine’s prototype, he wrote “Big Boy” at the front. Was it fitting? Sure because the engine was massive and at that time, it was the most powerful locomotive built.

Fan Railer, CC BY-SA 4.0, Wikimedia Commons

Fan Railer, CC BY-SA 4.0, Wikimedia Commons

Fuel Sources

All the main Big boy’s fuel source was coal. However the #4005 was the experimental locomotive on burning fuel oil and it presented three main problems: uneven heating in the single-burner firebox, unsatisfactory operation, and the smoke blocking the engineer’s line of sight. This oil configuration was never fully operational.

E's & D's Adventures in Life, CC BY 2.0, Wikimedia Commons

E's & D's Adventures in Life, CC BY 2.0, Wikimedia Commons

Norfolk And Western Class J (1941–1950)

Around the same time, Norfolk and Western Class J came up with the most powerful steam technology: a 4-8-4 engine. This version could pull heavy passenger trains at a speed of up to 110 mph (177 km/h) on flat terrain. The only problem? It was sensitive to subpar tracks.

Cak22, CC BY-SA 3.0, Wikimedia Commons

Cak22, CC BY-SA 3.0, Wikimedia Commons

Ran Along Various Routes

During the Class J locomotive operational years, it pulled passenger trains across multiple routes—Norfolk and Cincinnati; Monroe and Bristol, Virginia. It also hauled mail ensuring all mail got to their owners along the route. The locomotive was designed by Franklin C. Noel with his wife helping with the final look.

Gary Lee Todd, Ph.D., CC0, Wikimedia Commons

Gary Lee Todd, Ph.D., CC0, Wikimedia Commons

Santa Fe 2-10-4 (1944–1945)

This locomotive was also referred to as the Texas type and it was principally used in the United States. In Canada, it was called the Selkirk type. It had two leading wheels, ten driving wheels and two pairs of trailing wheels. This wheel alignment allowed for a larger firebox—burn more fuel at once.

Jack Delano, Wikimedia Commons

Jack Delano, Wikimedia Commons

International Acclaim

Santa Fe was also quite popular outside the United States. There was one in the Belgian Congo, a few in Canada, and several in Brazil, Japan, the Soviet Union, and South Africa. In the Soviet Union, they were only used for testing and later returned to the builder.

Unknown Author, Wikimedia Commons

Unknown Author, Wikimedia Commons

Preservation Efforts

You will find a few models of the Santa Fe preserved in a few locations in North America. Some notable locations are the National Museum of Transportation, St. Louis, MO (5011), Heritage Park Historical Village, Calgary, AB (5931) and Texas State Railroad, Palestine, TX (610). FYI, the numbers in brackets are road numbers.

Renelibrary, CC BY-SA 4.0, Wikimedia Commons

Renelibrary, CC BY-SA 4.0, Wikimedia Commons

Chesapeake & Ohio Class J3a Greenbrier (1948)

Steam technology lingered for years and even bore the Chesapeake & Ohio Class J3a Greenbrier by Lima Locomotive Works, but it was part of an earlier series. The name Greenbrier was inspired by the Greenbrier Hotel in White Sulphur Springs, West Virginia. It seemed fitting as this hotel lay on the train’s route.

jpmueller99 from Shenandoah Valley of VA, USA, CC BY 2.0, Wikimedia Commons

jpmueller99 from Shenandoah Valley of VA, USA, CC BY 2.0, Wikimedia Commons

Its Purpose

This locomotive’s purpose was to pull the long, heavy, and fast passenger trains C&O Railway owned. An example would be George Washington, which ran from Washington, D.C., Ohio, and Cincinnati, covering a distance of 599 miles (964 km). These versions were built in three batches.

Jarek Tuszyński / CC-BY-SA-3.0, CC BY-SA 3.0, Wikimedia Commons

Jarek Tuszyński / CC-BY-SA-3.0, CC BY-SA 3.0, Wikimedia Commons

One Out Of Ten Still Around

The J3a used coal as fuel and could move at a speed of 100 mph (160 km/h). Out of the total ten made, only one—the 614—remains preserved and is currently on display in Clifton Forge, Virginia, at the C&O Railway Heritage Center.

jpmueller99 from Shenandoah Valley of VA, USA, CC BY 2.0, Wikimedia Commons

jpmueller99 from Shenandoah Valley of VA, USA, CC BY 2.0, Wikimedia Commons

EMD F7 Diesel-Electric Locomotive (1949–1953)

This model was among the locomotive creations that represented the advancement and popularity of diesel to electric transition. It produced 1,500-horsepower and was moving at a maximum speed of 65–72 mph (105–116 km/h). This version was the fourth in the Electro-Motive Division of General Motors (EMD) line up.

Its Successors Had Higher HP

The F7 succeeded the F3, jumping the numbers 4, 5, and 6. But why? It was intentional, as the numbers were basically the version of a locomotive with specific features and improvements. The main difference? Horse power—F3 1,350; F7 1,500; F9 1,750.

Drew Jacksich, CC BY-SA 2.0, Wikimedia Commons

Drew Jacksich, CC BY-SA 2.0, Wikimedia Commons

Two Versions

These locomotives were a great feat of American ingenuity due to the successful dual usage—passenger and cargo.They also came in two versions A and B units. A units (2,393 in total) were cab-equipped (the engineer could fully operate the train) with a bulldog nose. B units (1,463) were cabless and weren’t independent.

Unknown Author, CC BY-SA 3.0, via Wikimedia Commons

Unknown Author, CC BY-SA 3.0, via Wikimedia Commons

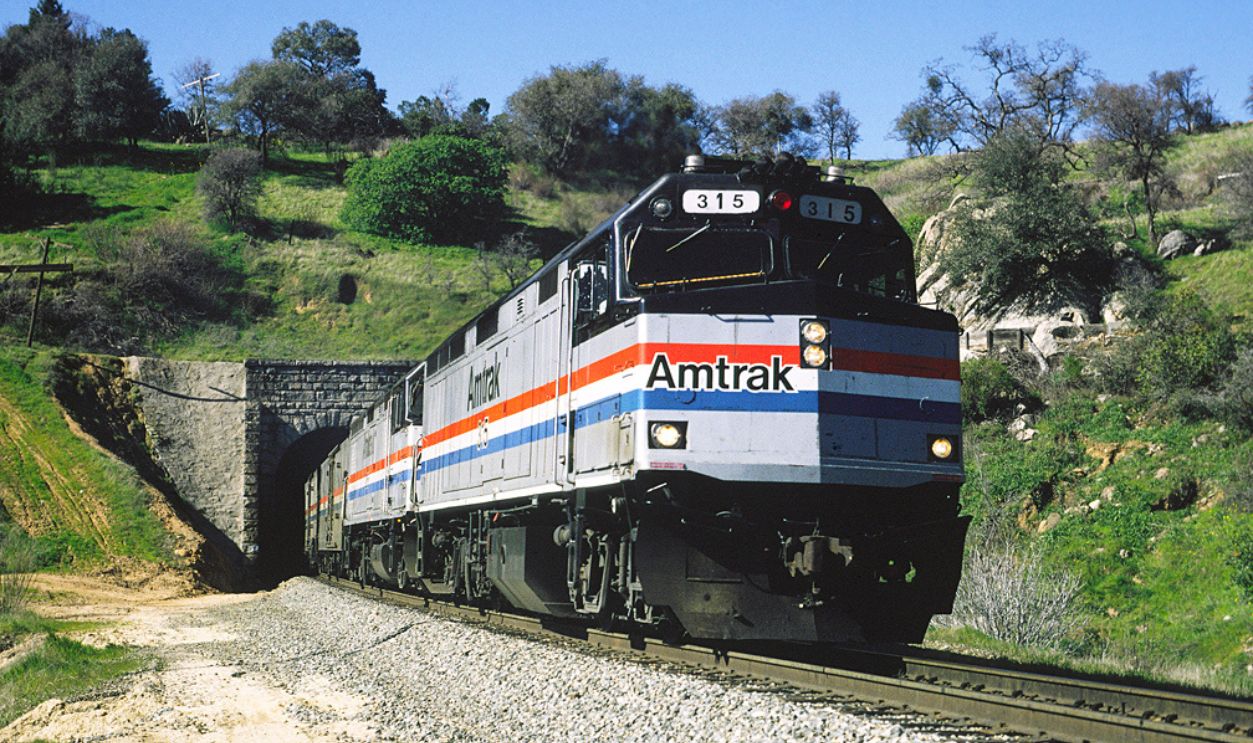

Amtrak F40PH (1976–1992)

Amtrak F40PH was the first American locomotive to have Head-End Power, also HEP, which replaced the older steam heat system. This system powered the passenger cars with lighting, heating, and cooling. The upgrade improved passenger comfort during the short Amtrak transit passenger routes.

Drew Jacksich from San Jose, CA, California Republic, CC BY 2.0, Wikimedia Commons

Drew Jacksich from San Jose, CA, California Republic, CC BY 2.0, Wikimedia Commons

The Two Axles Were Life-Changing

This General Motors locomotive was a two-bogies four-axle B-B, which basically means that each bogie had two axles. For context, an axle holds up a train’s weight, helping it distribute weight evenly while moving. They give the locomotive and the train stability with better traction and maneuverability.

Drew Jacksich, CC BY 2.0, Wikimedia Commons

Drew Jacksich, CC BY 2.0, Wikimedia Commons

Powerful Speed

Besides stability, this Amtrak locomotive was also a powerful 3,000–3,200 hp B-B diesel-electric, and it came in a few configurations that preceded Amtrak’s failed EMD SDP40F due to constant derailment issues. In 2023, extending to this year (2024), Rolling Stock Solutions started rebuilding a few F40PHs for leasing.

Drew Jacksich from San Jose, CA, The Republic of California, CC BY 2.0, Wikimedia Commons

Drew Jacksich from San Jose, CA, The Republic of California, CC BY 2.0, Wikimedia Commons

General Electric Dash 9 Series (1993–Present)

The Dash 9 Series locomotives are the most common on American rail tracks and they run on diesel. These locomotives come in various models—in four six-axle and one eight-axle model. All models have an electric fuel injection and split cooler, and they are all powered by a 16-cylinder, turbocharged, G.E. 7FDL 4-stroke diesel engine.

Morven, CC BY-SA 3.0, Wikimedia Commons

Morven, CC BY-SA 3.0, Wikimedia Commons

Technology Is Astounding

The traction on this bad boy is also quite impressive; a HiAd high adhesion truck that keeps the locomotive glued to the tracks, even when carrying heavy loads. This system also helps during harsh weather conditions. The wheelslip is microprocessor controlled, meaning a computer oversees braking, power, traction, and grip.

Morven, CC BY-SA 3.0, Wikimedia Commons

Morven, CC BY-SA 3.0, Wikimedia Commons

So Many Updates

The six-axle models are the C40-9 (4,000), C40-9W (4,000- upgraded to 4,400 hp), C44-9W (4,400 hp), and the C-38AChe (5,100 hp). Additionally, the C40-9 has rooftop-mounted air conditioners; C40-9W a wider cab; C44-9W more power; C-38AChe excels at high-altitude operations. The eight-axle BB40-9W outputs 4,000 hp.

John Mueller, CC BY 2.0, Wikimedia Commons

John Mueller, CC BY 2.0, Wikimedia Commons

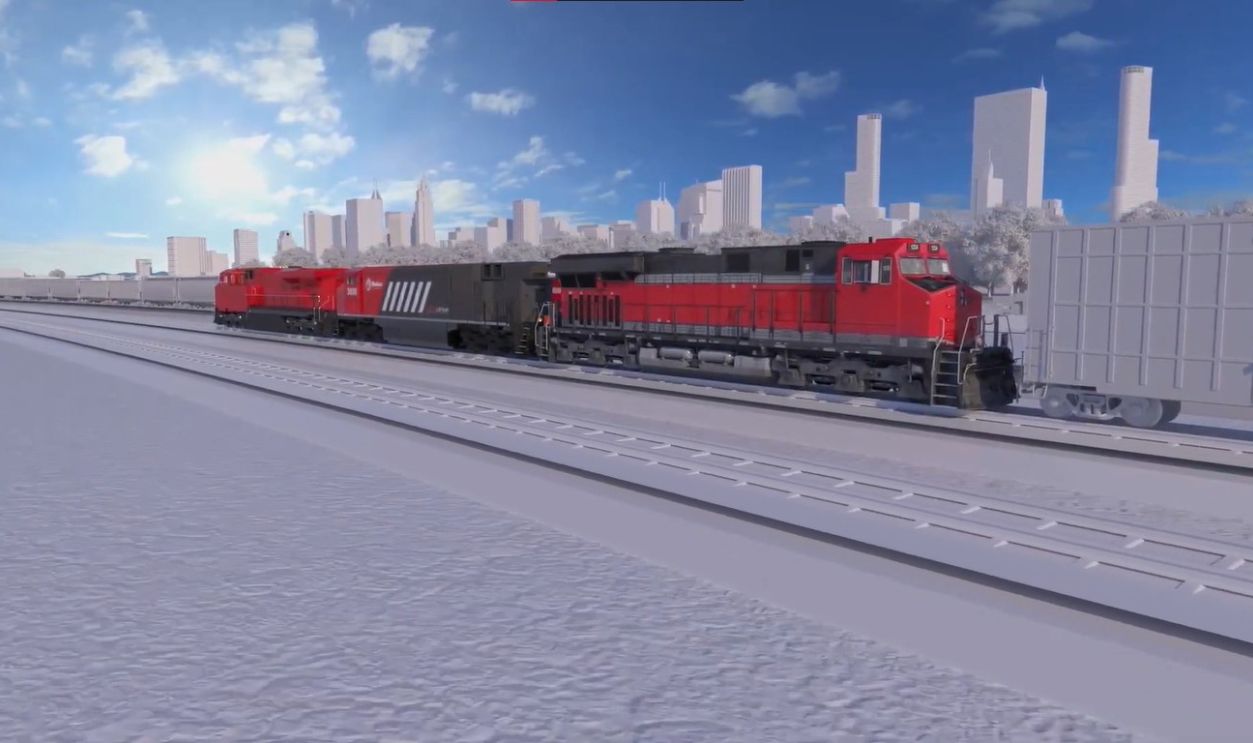

Union Pacific Hybrid Locomotive And ZTR (2022)

We are in the age of hybrid engines, and so, as expected, locomotives are also making the shift. The Union Pacific and ZTR project is developing hybrid battery-electric locomotives. Union Pacific is a railroad company that has been in operation since 1862. What about ZTR?

JeremyA, CC BY-SA 2.5, Wikimedia Commons

JeremyA, CC BY-SA 2.5, Wikimedia Commons

A Work-In-Progress

ZTR is a green tech company and they have started building these locomotives at the Union Pacific’s North Little Rock, Arkansas, facility. The prototype was ready in 2023 and testing already happened in May 2024. Five units of this ingenuity are expected to have arrived by the end of 2024.

Drastic Change In Fuel Consumption

Curious as to how they will work? Well, it’s the same as plug-in hybrid cars that run on both diesel and batteries—no more steam or coal. Just like cars, these locomotives will also be able to switch between multiple modes: single engine, battery charging, and electric mode. Expect 80% less fuel consumption with these.

Union Pacific Unveils Hybrid Battery-Electric Locomotive Prototype by Union Pacific

Union Pacific Unveils Hybrid Battery-Electric Locomotive Prototype by Union Pacific

Wabtec FLXdrive (2018–Present)

Another company working on creating eco-friendly locomotives is Wabtec and they are exploring the use of hydrogen as locomotive fuel. Yup, you read right, hydrogen. But that’s not all as they already have a fully operational battery-electric, heavy-haul locomotive with four axles powered by 20 racks of lithium-ion battery cells.

Wabtec's BEL FLX Drive locomotive returns to Erie. What next? By All Trains Great And Small

Wabtec's BEL FLX Drive locomotive returns to Erie. What next? By All Trains Great And Small

Optimized Battery And Design

This genius invention is the FLXdrive and here is how it works; it uses an intelligent energy management system that optimizes battery life and its efficiency. It also includes regenerative braking and a modular design, allowing seamless integration across vast rail vehicles.

Wabtec introduces battery powered locomotive to help reduce fuel energy by JET24 FOX66

Wabtec introduces battery powered locomotive to help reduce fuel energy by JET24 FOX66

Goals And Aspirations

The FLXdrive also has a liquid-cooling battery. Additionally, it also has an exclusive thermal management system, a D.C. fast-charger, and they also propose to add a moving-charger to reduce transit delays for charging. The goal here is to enhance reliability, performance, eco-friendliness, and most importantly safety.

FLXdrive™ | Battery-Electric Locomotive Technology by Wabtec Corporation

FLXdrive™ | Battery-Electric Locomotive Technology by Wabtec Corporation

Progress Rail EMD Joule Locomotive (2020–Present)

As locomotive development advances, Progress Rail gives us the battery-electric SD40JR in five different models. This locomotive has an asynchronous traction drive with individual axle control. Progress Rail introduced the battery-electric EMD Joule in 2020, with PHL as one of its first customers.

The EMD® Joule SD40JR Battery-Electric Locomotive – Testing in Pueblo by Progress Rail

The EMD® Joule SD40JR Battery-Electric Locomotive – Testing in Pueblo by Progress Rail

Advanced Charging Stations

The Joule's maximum speed is 80 km/h, with a starting tractive effort of 600 kN and a continuous tractive effort of 416 kN. It has specially designed stationery charging stations enabling rapid full recharging in less than four hours. Once charged, the SD40JR can operate continuously for up to 24 hours.

The EMD® Joule SD40JR Battery-Electric Locomotive – Testing in Pueblo by Progress Rail

The EMD® Joule SD40JR Battery-Electric Locomotive – Testing in Pueblo by Progress Rail

Wabtec And General Motors HYDROTEC (2018–Ongoing)

Jumping into the hydrogen project, Wabtec is looking into hydrogen as fuel because it’s clean energy—no greenhouse gas emissions when combusted. Wabtec is working in collaboration with GMC to make this happen. With a shared vision, the two companies signed a nonbinding memorandum of understanding on June 15, 2021.

GM Displays Hydrogen Fuel Cell Tech by Breaking Defense

GM Displays Hydrogen Fuel Cell Tech by Breaking Defense

No Prototype As Of Yet

The HYDROTEC hydrogen fuel cell systems are to be integrated into the already existing Wabtec’s locomotives. There has not been any prototype of this genius concept yet, but Wabtec forecasts to have it by 2027. Are you excited to see how it turns out? We, and a million others, are too!

Wabtec Has Deal With GM To Develop New Type Of Railroad Locomotives by CBS Pittsburgh

Wabtec Has Deal With GM To Develop New Type Of Railroad Locomotives by CBS Pittsburgh

Good And Bad News

The one significant downside is that hydrogen is still significantly expensive, and so, this project might not be viable in this current time. This is according to Philip Moslener, Wabtec’s corporate V.P. for advanced technologies. But the good news is that hydrogen production is said to rise; lowering its cost.

Wabtec Has Deal With GM To Develop New Type Of Railroad Locomotives by CBS Pittsburgh

Wabtec Has Deal With GM To Develop New Type Of Railroad Locomotives by CBS Pittsburgh